Current Research: Micromechanics of

deformation and fracture of Mg and Al (gravity and HPDC) casting alloys;

Pseudoelastic behaviour of Mg-Al alloys; Hardness behaviour of Mg alloys;

Strengthening effects in single crystals of Mg-Al and Mg-Zn; Hall-Petch

effects in Mg-Zn and Mg-Al alloys; Creep of HPDC Mg alloys. Short Range

Order and precipitation in binary Mg alloys. Microstructure of Al-Cu-Si-Mg

casting alloys. Environmental issues related to light alloys in

transportation. Methods in Materials Selection.

Some examples of what I do:

Damage Mechanisms

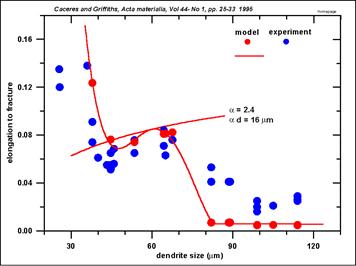

Some of

the oldest unresolved questions in cast Al-Si-Mg alloys refer to the

respective roles played by the dendrite cell size and the size/shape of the

Si particles on the material's ductility. Metallography provides a clue:

Dendrites divide the material into boxes,

as grain boundaries do. Following MF Ashby's theory of plastically

non-homogeneous materials, it is easy to show that small dendrites should

produce more strain hardening, enhancing particle cracking, hence lowering

the ductility. On the other hand, Si particles tend to be longer when the

dendrites are large. Long Si particles trap more dislocations, causing more

strain hardening and, because they are easier to crack, less ductility.

These two opposing tendencies in the strain hardening and damage rate

result in a maximum in the ductility at intermediate cell sizes. See the

predicted (red lines and circles) and measured (blue circles) ductility in

the figure below.

The tensile ductility

of alloy A356 as a function of the dendrite cell size. (Cáceres, C.H., Griffiths, J.R., "Damage by the Cracking of Si

Particles in an Al-7Si-0.4Mg Casting Alloy", Acta

Materialia, 44, 25-33, 1996)

The

calculated lines and points are from a model developed with John Griffiths (CSIRO, Pinjarra

Hills). This work combines Weibull statistics

with Brown and Stobbs' theory of dispersion

strengthening, and merited reviews at the invited lectures to the 1995 and

2000 Meetings of the American Foundry Society by Prof John Berry from Mississippi State University.

The bump in the ductility at intermediate dendrite sizes is present in

both, alloy A356 and A357

Quality Index

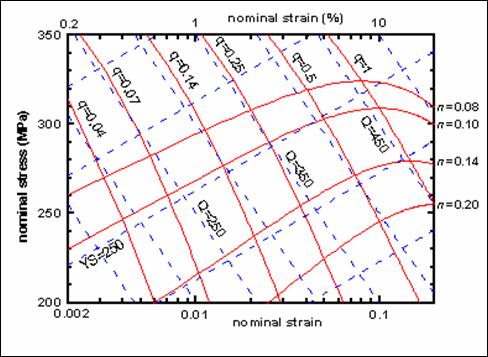

People in the

casting industry often use Quality Index charts to compare alloys and

processes. These clever charts, invented by Michel Drouzy,

Sylvain Jacob and Michel Richard in the 70's, tell you whether the material’s

properties change for the better (or otherwise) when you modify the process

or the chemistry.

In 1997 I

developed an analytical method for creating the charts and gave physical

meaning to the QI by referring the alloy's quality to the necking onset

strain (see Chart). This mathematical trick landed me the Best Paper Award

by the International Journal of Cast Metals Research in 1998 and merited a

dedicated review at the 2000 AFS invited lecture by Sylvain Jacob.

The

original QI charts were intended only for alloy A356, but the analytical

method extends them to any  material. In joint efforts with a number of

people, the charts have been applied to Al-Cu

and Al-Si-Cu alloys.

material. In joint efforts with a number of

people, the charts have been applied to Al-Cu

and Al-Si-Cu alloys.

A Quality Index chart.

Blue

lines: empirical lines (as determined by Drouzy,

Jacob and Richard., 1980); Red lines: calculated.

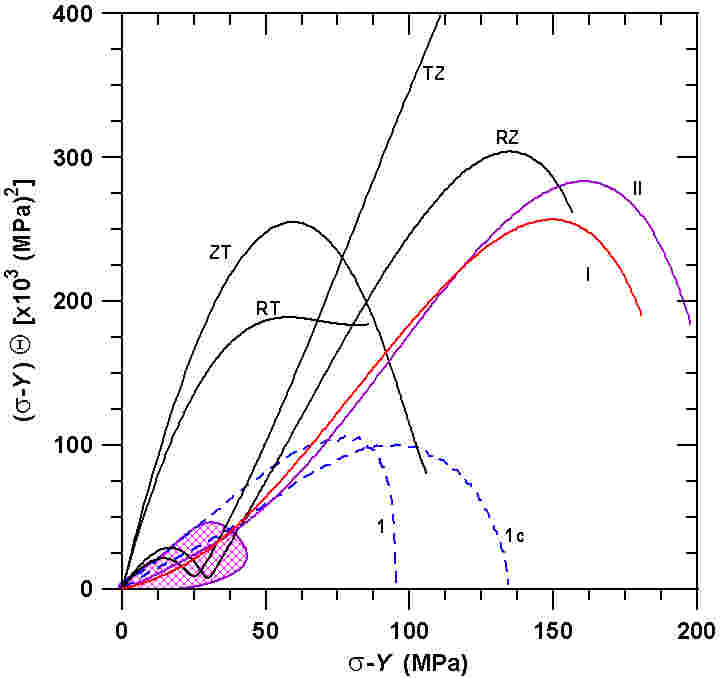

Twinning

in Mg

Recent work (with

Andrew Blake) and Pavel Lukac from Charles University,

was on the hardening caused by {10-12} twinning in Mg. Using the

Kocks-Mecking-Estrin phenomenological analysis,

we showed that twinning hardly introduces any hardening. The reason? Due to

their small intrinsic shear strain (~0.12), {10-12} twins in Mg are way too

big, unlike in other metals where because of their large shear strain they

are bound to remain small. Thus, any grain partition effects in Mg are

quickly overrun by the athermal forest hardening that develops once the

profuse twinning stage is over. This is shown by the figure: where the lines represent the

dislocation hardening. Twinning accounts for the hardening inside the pink area

near the origin. [Cáceres, C.H., P. Lukác

and A. Blake, "Strain Hardening due to Twinning in Pure Magnesium

", Philos. Mag. A, 2008, 88, 991-1003] DOI: http://dx.doi.org/10.1080/14786430701881211

This is shown by the figure: where the lines represent the

dislocation hardening. Twinning accounts for the hardening inside the pink area

near the origin. [Cáceres, C.H., P. Lukác

and A. Blake, "Strain Hardening due to Twinning in Pure Magnesium

", Philos. Mag. A, 2008, 88, 991-1003] DOI: http://dx.doi.org/10.1080/14786430701881211

3D

FIB reconstruction of the intermetallics in HPDC Mg-Al alloys

These beautiful

images are the result of painstaking work by AV Nagasekhar, a Postdoctoral

fellow working with me in 2008-2010 (Currently with Carpenter Technology, US). The

percolating intermetallics introduce a strong elastic constraint on the Mg

matrix near the casting surface, accounting for a large share of the so

called skin effect. MPEG files

showing the full 3D structures are available at: http://dx.doi.org/10.1016/j.matchar.2010.06.007

Earlier Work

During

the 1980's I worked on serrated flow in aluminium alloys and, jointly with

David Wilkinson from McMaster University, on superplastic materials, creep

fracture of alumina and processing of ceramic powders. The work on

serrated flow and superplasticity merited reviews by Neuhäuser

and Schwink, and Mukherjee, respectively, in the

series Materials Science and Technology (Editors: RW Cahn, P Haasen and EJ Kramer; VCH, New York, 1991), Vol. 6:

Plastic deformation of materials, pp. 221 and 416-433.